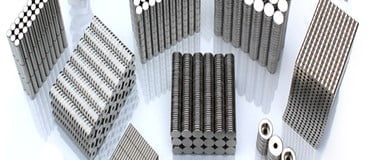

Generally, all the magnets have a certain measurable energy density from which some magnets with greater strengths are regarded as extremely powerful compared to the other magnets. The figure shows five different magnets rated based on their strengths:

Neodymium Magnets

Did you know around 45 to 50,000 tonnes of neodymium magnets are manufactured worldwide?

If we say “strongest magnet,” we usually refer to neodymium magnets, these magnets are the most known type of strongest magnets and require protective coating and high magnetizing fields for their different applications. Because of their strength, they are the best magnet to use for magnet fishing!

They are the strongest and smallest magnets, showing great strength even in small sizes. Also, they are more compact and produce more energy per volume. They provide resistance to diamagnetism and unparallel levels of magnetism compared to other magnets.

Moreover, these magnets have eight different commercially used grades ranging from N35 to N52. They are graded based on maximum energy product, with N35 grade providing the weakest while N52 providing the greatest magnetic strength.

They are commercially available popular magnets that can be found anywhere around the globe. Industries like medical science, electrical motor, renewable energy, manufacturing, motor vehicle, and technology greatly rely on these magnets.

Samarium Cobalt Magnets

Did you know? these magnets are regarded as the first rare earth magnets that are available commercially. Also, these magnets are powerful but have lesser power when compared to neodymium magnets. They have a regular operating temperature of 80 0C and have excellent corrosion resistance. Usually, the strength of these types of magnets can be altered by cooling or heating them below 0 0C. Basic applications of these magnets are found in medical devices, generators, MRI machines, and motors

Moreover, there are eleven different subgrades of these magnets that are further grouped into two main types: Samarium Cobalt (1-5) and Samarium Cobalt (2-17). These titles are given to these groups based on their samarium atoms to cobalt atoms or their ratio for example 1-5 range consists of one samarium atom per five cobalt atoms.

Ceramic or Ferrite Magnets

Due to their excellent electrical insulation ability, they are known as Ceramic. They are composed of ceramic materials with high magnetization resistance, which means they cannot be magnetized or demagnetized easily. Also, they have low saturation, so they cannot hold their magnetic field very well and don’t generally stay magnetized for long periods.

Other features include:

- They are electrically insulating- that means they do not allow eddy currents inside them

- They are ideal for low-cost applications

- They are not ideal for cold temperatures but work great for higher temperatures

Alnico 5 and Alnico 8

Generally, Alnico 8 and Alnico 5 are not identical but are made of the same alloy. Alnico 5 is used widely as one sintered and four cast versions. They can deliver magnetic energy economically to the magnetic circuits. Moreover, Alinco 8 offers a great alternative to ceramic magnets. They are strong with a naturally aggressive tone. In general, Alnico 5 has the lower coercive force and higher residual induction while Alinco 8 has the higher coercive force and lower residual induction. Moreover, Alinco 8 is stronger than Alinco 5 but is less magnetic.

Flexible Magnets

These magnets are found just about anywhere! These magnets are used in many applications, from credit card magnetic strips to the magnets used in wristbands and watches. Also, they are used in medical devices like hearing aids and pacemakers.

These magnets are not strong as their rigid counterparts, but they offer a variety of advantages as they play an important role in making these magnets popular in boats and cars. Furthermore, they have the ability to withstand heat up to 180°F without becoming brittle or losing much of their magnetism. Additionally, compared to other types of permanent magnets, they are also lightweight.

Sources

- Magnet Blog: What is a Strong Magnet?

- Licensed Material Neodymium Magnets

- Magnetic properties of neodymium magnets